all-day wearable motorcycle apparel

At SA1NT, we create all-day wearable motorcycle apparel that not only features world-first abrasion protection, but looks as good on the bike as it does off it.

The search for UNBREAKABLE is an all-consuming affair. From the day we founded SA1NT we have relentlessly chased down every opportunity to create fabrics that look, feel and sit just like the fashion materials you know and love, but that integrate space-age fibres which deliver unparalleled single-layer protection.

What is Dyneema® and why do we use it over Kevlar®?

Our initial goal was to develop a single layer fabric that would exceed the CE-13595 Protective Motorcycle Apparel Standards in place at the time, however this proved a real challenge using Kevlar®.

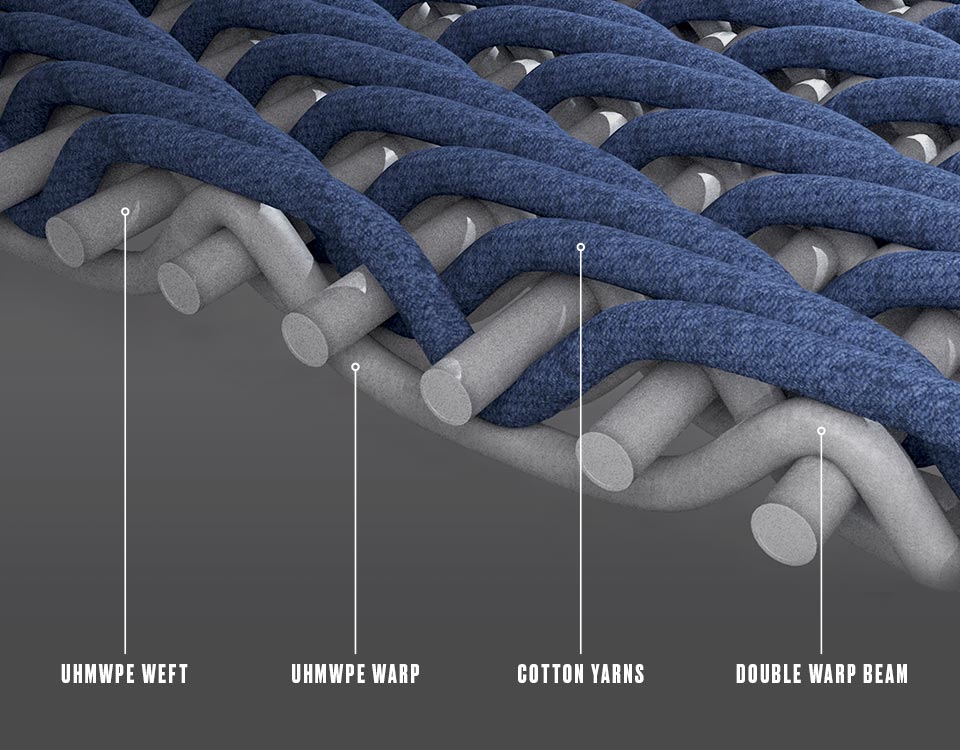

To achieve our goal meant going deeper, and it was during this research phase that we discovered the world’s strongest fibre: Dyneema®. Dyneema® is a trademarked brand name of ultra-high molecular weight polyethylene (UHMWPE)— a high-density material that can be spun like cotton and feels great to wear. Dyneema® gave us the strength and abrasion resistance we required while allowing our jeans to look and feel like regular denim.

MOTOWEAR TECHNOLOGY

Dyneema was the key to unlocking our vision of an AA-rated PrEN 17092-1:2017 single-layer fabric for abrasion resistance. Instead of placing bulky layers and liners into our jeans, we wove Dyneema® fibres into the warp and weft of our denim to create a completely single-layer protective fabric that looks and feels just like regular denim.

SEAM STRENGTH

Seam strength is another important factor in ensuring protective garments keep you safe – there’s no point having the world’s toughest denim if it all falls apart at the seams! SA1NT denim seams are tested using a tensile testing machine which pulls the seam apart and measures the force required for a break to occur.

ABRASION RESISTANCE

SA1NT denim is tested using the Darmstadt method to simulate a rider sliding along a road surface. The Darmstadt method involves sliding fabric samples across a concrete surface from an initial set speed until standstill and fabrics can only achieve a pass if there are no holes with an opening of 5mm or more on each fabric sample taken from garment.

IMPACT ABSORPTION

For motorcycle garments to meet the new European EN17092 Class A, AA, AAA safety standards, impact protection armour must be present within the garment and must be positioned to cover the appropriate body part relevant to the impact protector. For motorcycle jeans, this includes armour to protect the knees and hips.

TEAR STRENGTH

This same test is used for the fabric itself with samples of the fabric essentially being pulled apart until failure. Tests are conducted along both the warp and weft of the fabric to ensure strength is retained in all directions.

ULTRA HIGH MOLECULAR WEIGHT POLYETHYLENE

+ IT’S THE WORLD’S STRONGEST FIBRE

+ IT’S USED IN APACHE HELICOPTER ARMOUR PLATING

+ IT’S 15 TIMES STRONGER THAN STEEL

+ IT MOORS SPACE SHUTTLES TO SPACE STATIONS

+ IT’S SA1NT’S SECRET SAUCE

+ IT FLOATS ON WATER

DOCUMENTS OF CONFORMITY

Use this text to highlight product features, link to pages or showcase your brand.